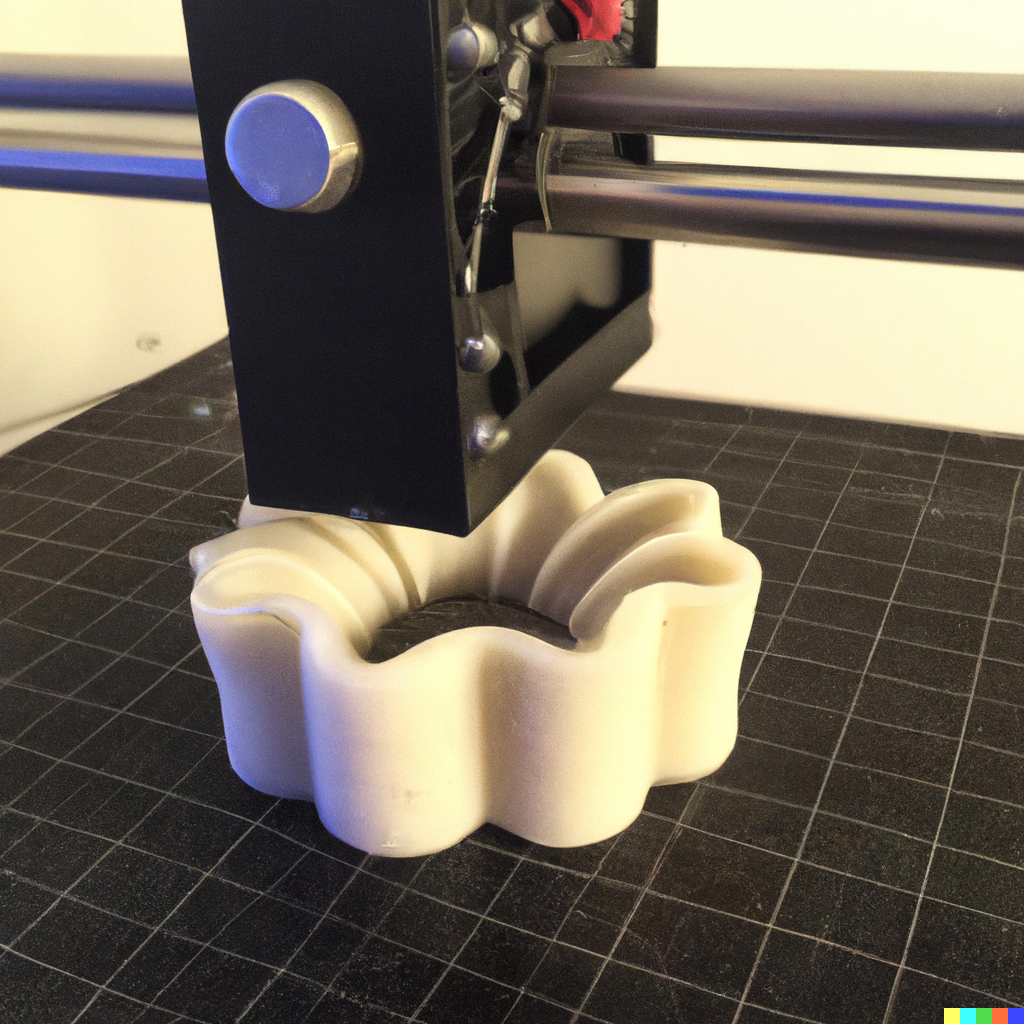

There are ongoing developments in materials science that are leading to the creation of new and better materials for 3D printing. Here are a few examples:

Biodegradable materials: While materials like PLA are biodegradable, they can take a long time to decompose. Researchers are working on developing new biodegradable materials that break down more quickly and are more environmentally friendly.

Conductive materials: Materials that can conduct electricity, like copper or graphene, can be used in 3D printing to create electronic devices and circuits. Researchers are working on developing new conductive materials that are easier to print and have better conductivity.

Self-healing materials: Self-healing materials can repair themselves when they are damaged. Researchers are working on developing self-healing materials that can be used in 3D printing to create objects that can repair themselves.

High-temperature materials: Some 3D printing applications require materials that can withstand high temperatures, such as those used in aerospace and automotive industries. Researchers are working on developing new materials that can withstand higher temperatures than current materials used in 3D printing.

Sustainable materials: Materials that are environmentally friendly and sustainable, such as recycled materials or materials made from renewable sources, are also being developed for use in 3D printing.

These new materials are likely to have a significant impact on the future of 3D printing and the industries that rely on it. As materials science continues to advance, we can expect to see more new and innovative materials that are better suited to 3D printing and have a lower environmental impact.

There are several materials currently used in 3D printing that are considered to be environmentally friendly:

PLA (polylactic acid) – PLA is a biodegradable and compostable thermoplastic made from renewable resources such as corn starch, sugarcane, and tapioca roots. It is one of the most commonly used materials in 3D printing and has a lower carbon footprint than traditional plastics.

PET (polyethylene terephthalate) – PET is a widely recycled material commonly used in the production of water bottles. It is a strong and durable material that is also recyclable and can be used for 3D printing.

Wood-based filaments – These filaments are made from a combination of recycled wood and binding polymers. They create 3D printed objects that have the look and feel of real wood.

Recycled materials – Many 3D printing filaments are made from recycled materials such as recycled plastics, recycled glass, and even recycled electronic waste. These materials help reduce the amount of waste in the environment and have a lower environmental impact than virgin materials.

It is important to note that while these materials are more environmentally friendly than traditional plastics, their environmental impact can still vary based on factors such as the energy used in production and transportation, as well as the disposal and end-of-life management of the 3D printed objects.

There are many materials that are better for the environment and can be used outside of 3D printing. Here are some examples:

Bamboo – Bamboo is a highly sustainable and renewable material that grows quickly and does not require pesticides or fertilizers. It can be used to make furniture, flooring, and even clothing.

Cork – Cork is a natural and sustainable material that is harvested from the bark of cork oak trees. It is often used in flooring, insulation, and as a sustainable alternative to plastic in packaging.

Recycled plastic – Recycling plastic can help reduce the amount of waste in the environment. Recycled plastic can be used to make a variety of products, including furniture, clothing, and building materials.

Hemp – Hemp is a sustainable and renewable material that can be used to make a variety of products, including clothing, paper, and building materials. It requires minimal water and does not require pesticides or herbicides.

Reclaimed wood – Reclaimed wood is wood that has been salvaged from old buildings, furniture, or other sources. Using reclaimed wood reduces the demand for new wood and helps prevent deforestation.

These materials have a lower environmental impact compared to traditional materials, but it is still important to consider the entire lifecycle of the products made from these materials, including the manufacturing, transportation, use, and disposal phases.

For Example, while hemp is a sustainable and renewable material that has many uses, using it as a 3D printing material would likely not be practical. Hemp rope is made by twisting together long fibers, which are not typically suitable for use in 3D printing.

There are several reasons why using hemp rope as a 3D printing material would be problematic:

Inconsistent filament diameter: Hemp rope is made up of twisted fibers, which means the filament diameter would be inconsistent. This could cause problems with the extrusion process and result in inconsistent printing.

Limited strength: Hemp fibers are not as strong as other materials used in 3D printing, such as PLA or ABS. This means that printed objects made from hemp rope would likely not be as strong or durable as those made from other materials.

Difficulty in feeding the filament: 3D printers require a consistent and reliable supply of filament to create objects. Feeding hemp rope through a 3D printer would be difficult, as the filament diameter would be inconsistent and the twisted fibers would be prone to tangling.

Limited availability: Hemp rope is not as widely available as other 3D printing materials. This could make it difficult to source, and it may be more expensive than other materials.

In summary, while hemp is a sustainable and renewable material with many uses, it is not a practical or suitable material for use in 3D printing. Other materials, such as PLA, ABS, and nylon, are better suited for use in 3D printing and offer more consistent and reliable results.