There are many reasons why 3D printing is awesome! Here are just a few:

Creativity and Customization: 3D printing allows you to turn your ideas and designs into physical objects. You can create anything from simple toys to complex machinery, and you can customize your designs to meet your specific needs and preferences.

Rapid Prototyping: 3D printing allows for rapid prototyping, which means you can quickly iterate and improve your designs. This can save time and money compared to traditional manufacturing methods.

Accessibility: 3D printing technology is becoming more affordable and accessible, which means more people can use it to create and innovate.

Education: 3D printing can be a powerful educational tool. It can help teach design thinking, engineering concepts, and used in a variety of medical applications, such as creating custom prosthetics, implants, and surgical tools. This technology has the potential to revolutionize healthcare by making personalized treatments more accessible and affordable.

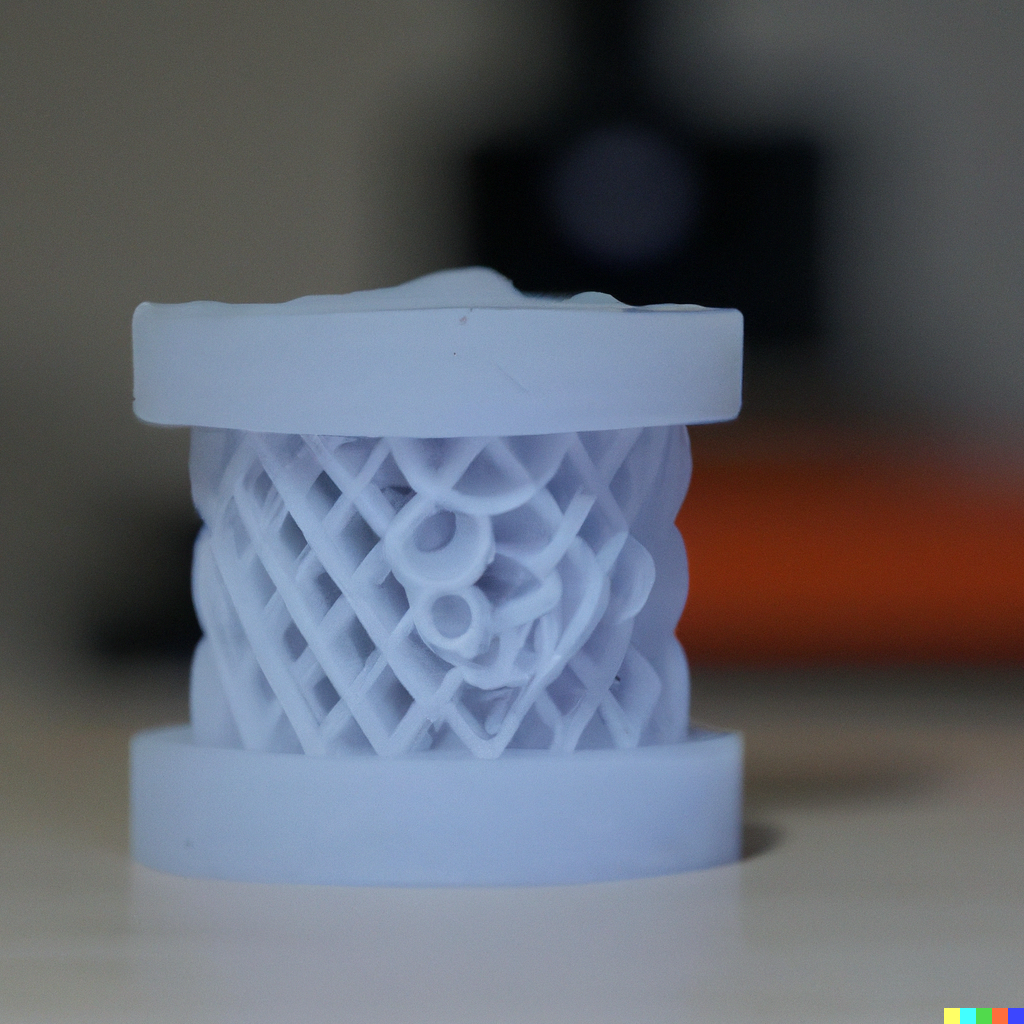

Art and Design: 3D printing has opened up new possibilities for artists and designers. It allows them to create intricate and unique designs that were previously impossible to achieve with traditional methods.

Overall, 3D printing is awesome because it allows for greater creativity, customization, accessibility, and sustainability, and has the potential to revolutionize many industries, from manufacturing to healthcare to art and design.

There are several different styles of 3D printers, each with its own strengths and weaknesses. Here are some of the most common types:

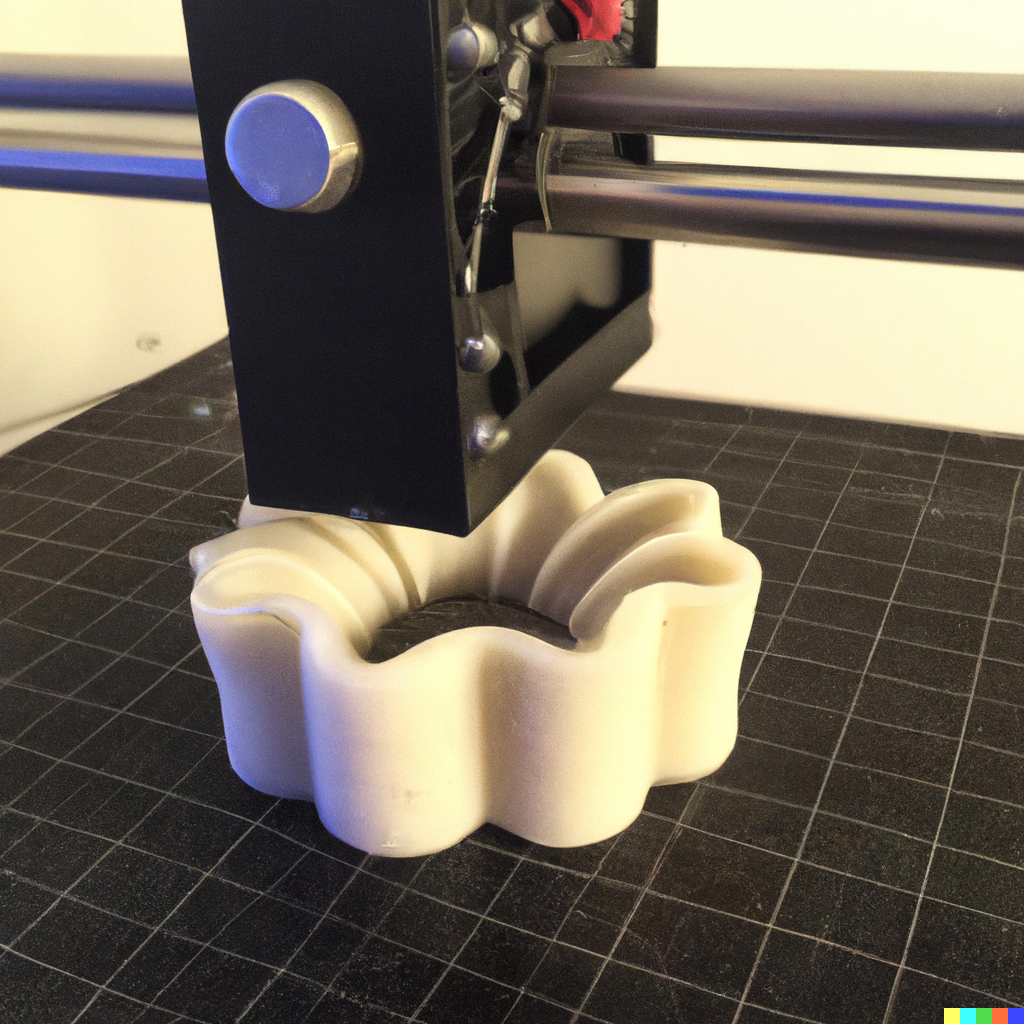

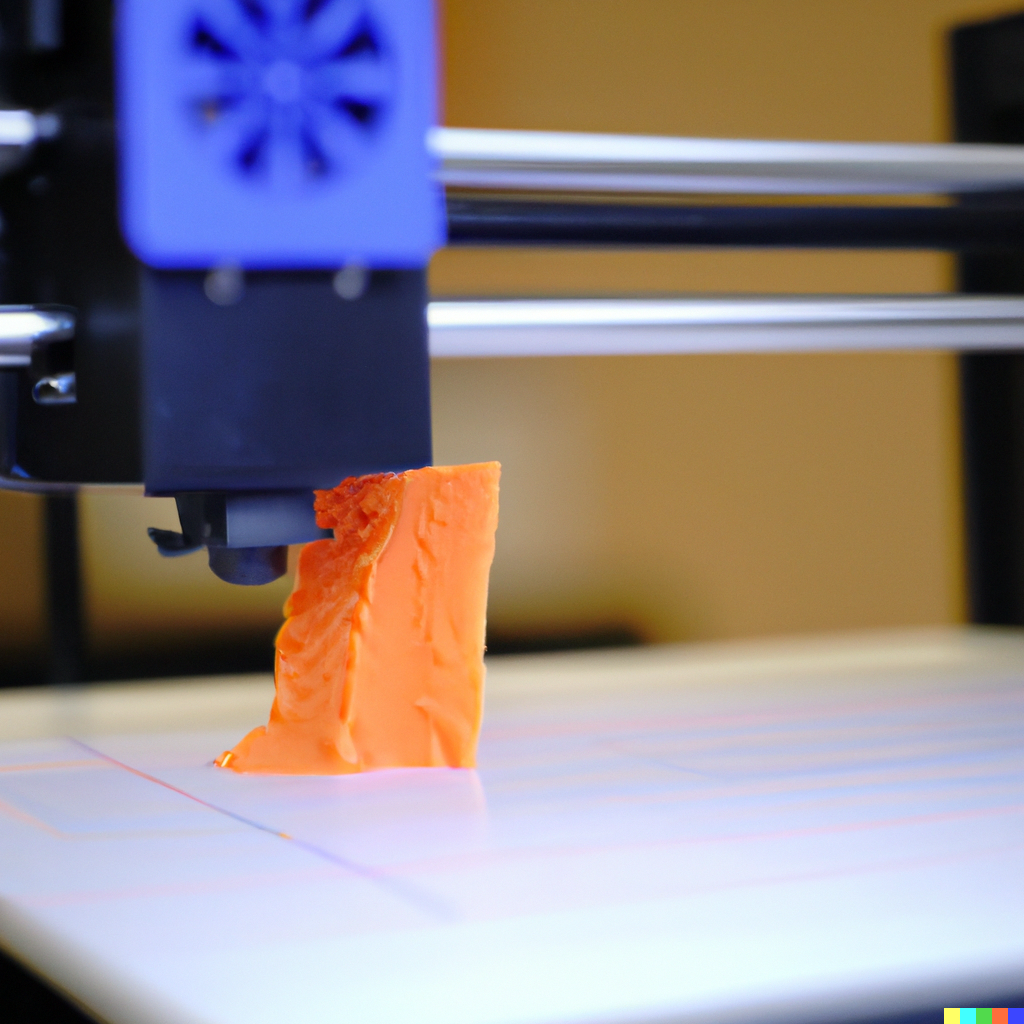

Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM): FFF/FDM printers are the most common type of 3D printer. They work by melting a plastic filament and extruding it layer by layer to create a 3D object. FFF/FDM printers are affordable, easy to use, and can print with a variety of materials, including PLA, ABS, PETG, and TPU.

Stereolithography (SLA): SLA printers use a laser to cure a liquid resin, building the object layer by layer. SLA printers can produce very high-quality prints with smooth surfaces and fine details, but they are generally more expensive than FFF/FDM printers and the resin can be messy and toxic.

Digital Light Processing (DLP): DLP printers are similar to SLA printers, but they use a projector to cure the resin instead of a laser. DLP printers can be faster than SLA printers, but the print quality may not be as high.

Selective Laser Sintering (SLS): SLS printers use a laser to fuse powder particles together to create the object. SLS printers can print with a variety of materials, including nylon and TPU, and they can produce very strong and flexible parts. However, SLS printers are generally more expensive than FFF/FDM printers and the printing process can be messy.

Binder Jetting (BJ): BJ printers deposit a liquid binder onto a powder bed, layer by layer, to create the object. BJ printers are generally faster than SLS and SLA printers, and they can print with a variety of materials. However, the parts may not be as strong as those produced by SLS printers.

These are just a few of the most common 3D printer styles. There are also hybrid printers that combine different technologies, such as FFF/FDM and SLA, to take advantage of the strengths of each.

The process for creating a 3D print generally involves the following steps:

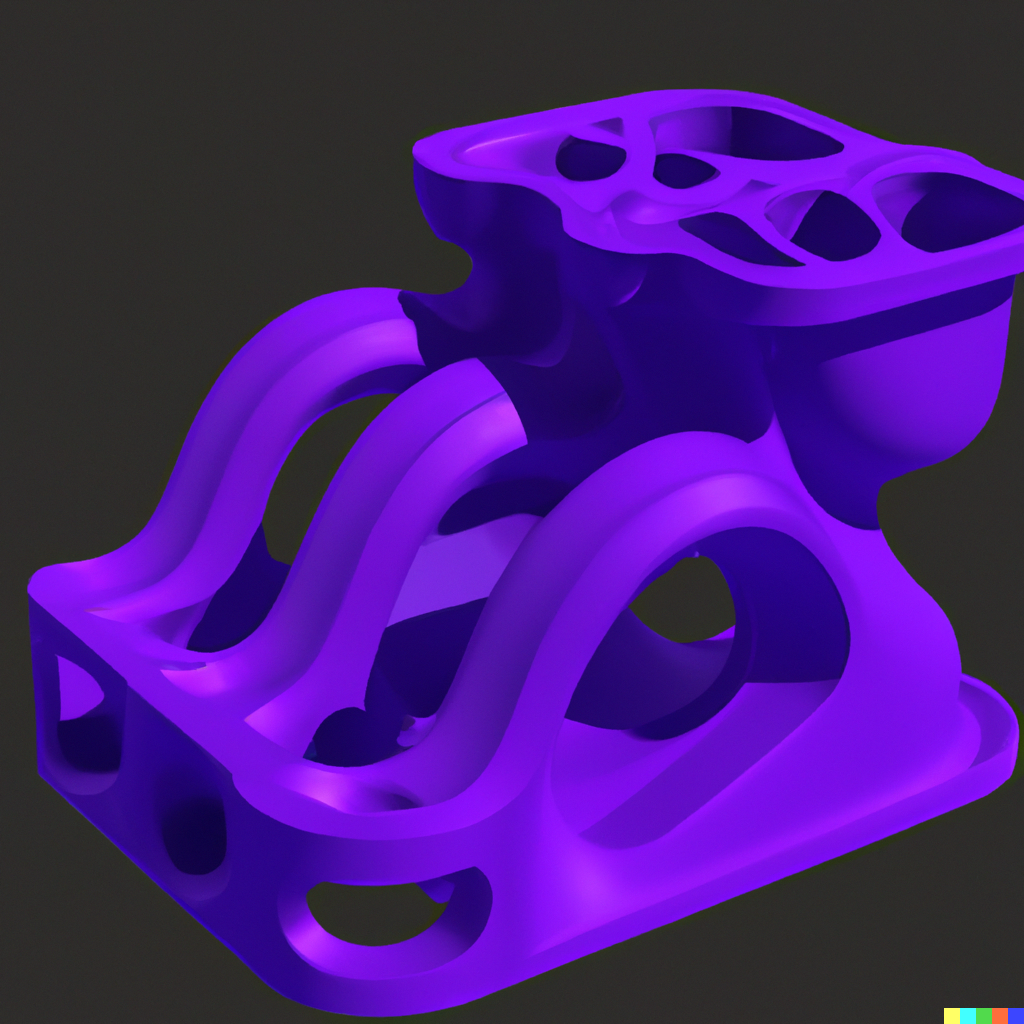

Create or obtain a 3D model: The first step is to create or obtain a 3D model of the object you want to print. This can be done using 3D modeling software, such as Blender or Autodesk Fusion 360, or by downloading a pre-made model from an online library.

Prepare the model for printing: Once you have the 3D model, you need to prepare it for printing. This involves making sure the model is “watertight” (i.e., there are no gaps or holes in the surface of the model), and adding any necessary support structures or rafts to ensure the model can be printed successfully.

Slice the model: After the model is prepared, it needs to be sliced into thin layers using slicing software. The slicing software will take the 3D model and break it down into a series of 2D layers that the printer can then print one layer at a time.

Send the file to the 3D printer: Once the model is sliced, the resulting file is sent to the 3D printer. The printer reads the file and begins to print the object layer by layer.

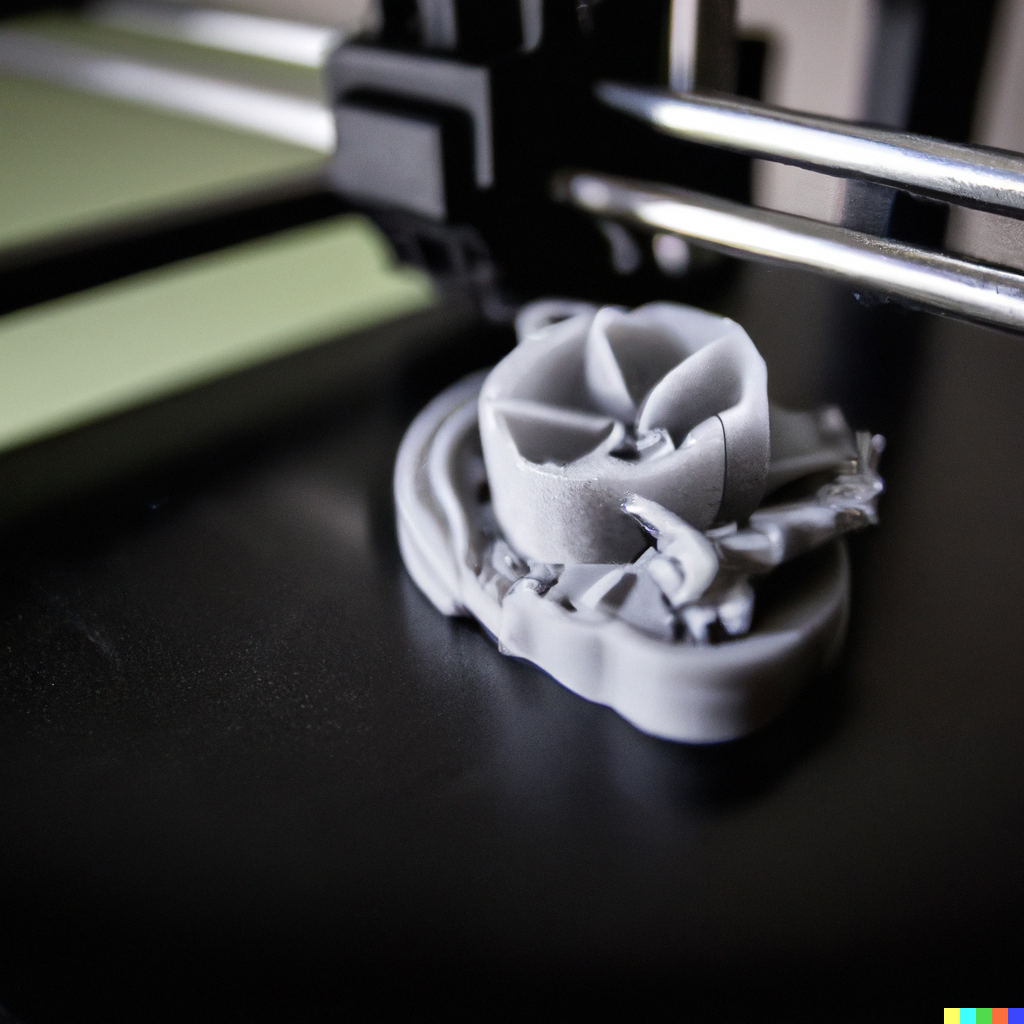

Print and post-process the model: The printer will print the object by melting and depositing a material (such as plastic or resin) layer by layer until the entire model is complete. After printing, the model may need to be post-processed, which can involve removing any support structures, sanding or painting the model, or curing the model with UV light (for certain types of resins).

These are the basic steps involved in creating a 3D print, but the specific details can vary depending on the type of printer and materials used.

There are several popular slicer software programs available for 3D printing, each with its own set of features and strengths. Some of the most commonly used slicers include:

Ultimaker Cura: Cura is a free, open-source slicing software that is widely used by 3D printing enthusiasts and professionals. It offers a user-friendly interface, a variety of advanced settings, and can slice models for a wide range of 3D printers.

PrusaSlicer: PrusaSlicer is another open-source slicing software that is specifically designed for use with Prusa 3D printers. It offers advanced features like automatic variable layer height and customizable support structures.

Simplify3D: Simplify3D is a paid slicing software that offers advanced features like multi-material printing, customizable support structures, and the ability to preview and optimize print settings. It supports a wide range of 3D printers.

Slic3r: Slic3r is a free, open-source slicing software that offers a range of advanced features like customizable support structures, variable layer heights, and multi-part printing. It supports a wide range of 3D printers and offers both a graphical user interface and command-line interface.

MatterControl: MatterControl is a free, open-source slicing software that offers a user-friendly interface, customizable support structures, and the ability to control multiple 3D printers from a single interface.

These are just a few examples of the many slicing software programs available for 3D printing. The best slicer for you will depend on your specific needs and preferences.

There are several challenges that one might encounter when getting into 3D printing:

Cost: 3D printers can be expensive, especially if you’re looking for a high-quality machine. Additionally, you may need to purchase additional supplies such as filaments, software, and maintenance materials.

Complexity: 3D printing involves a number of technical considerations, including choosing the right settings for your print, calibrating the printer, and troubleshooting problems. The learning curve can be steep, particularly for beginners.

Software: 3D printing requires the use of specialized software, such as CAD (Computer-Aided Design) software or slicers that prepare the 3D models for printing. Learning how to use these programs can take time and effort.

Quality control: The quality of your prints can vary depending on a variety of factors, such as the type of filament, printer settings, and print design. Achieving consistent and high-quality results can take practice and experimentation.

Safety: Some materials used in 3D printing, such as certain types of plastics, can emit harmful fumes when melted. It’s important to take precautions to